PEEK (Polyetheretherketon) 1000

Back to PEEK

Material Information

The newly available black PEEK 1000 is ideal for instrument components where aesthetics are important, as well as for seal components where ductility and inertness are important.

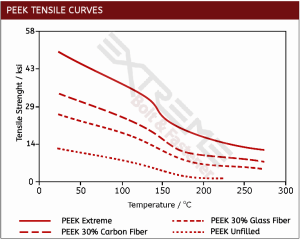

This general purpose grade is unreinforced and offers the highest elongation and toughness of all PEEK grades. Peek 1000 is a chemically resistant structural, bearing & wear material for continuous use up to 480°F (250°C). Very low moisture absorption. Inherently good wear and abrasion resistance. PEEK 1000 is unaffected by continuous exposure to hot water or steam. Ketron® PEEK grades offer chemical and hydrolysis resistance similar to PPS, but can operate at higher temperatures.

The composition of the raw materials used for the production of the KETRON PEEK 1000 natural stock shapes complies with the directives of the American FDA regulations (requirements CFR 21 Section 177.2415 & 177.2416 and ASTM D6262 S-PAEK 0111) concerning plastic materials intended to come into contact with food.

These features, adds to its excellent ability to sterilize by means of steam, dry heat, ethylene oxide and gamma radiation, make this grade very popular in medical, pharmaceutical and food processing industries

Application Overview

-

Proven Applications

- Aircraft components

- Wire and cable coatings

- Automotive engine parts

- Tearings

- Woven monofilament

- Film

- Microwave applications

- Pump and valve parts

- Chemical processing

- Electrical components and electronics

- Semiconductor production

- Industrial applications