When engineers need reliable and durable components, they often turn to Vespel® plastic. This polyimide material has a reputation for its exceptional thermal stability and mechanical strength. It provides support in a wide range of environments. Engineers across industries find Vespel® invaluable for many applications. Learn about five common applications for Vespel® plastic.

Bushings

Vespel® plastic offers engineers a strong, dependable material for bushings. Its low coefficient of friction and tolerance for extreme temperatures make it ideal for applications in the automotive and aerospace industries. By reducing mechanical abrasion, Vespel® bushings enhance operational efficiency in machinery and systems facing constant use and high heat.

Valve Seats

Another common application for Vespel® plastic is the manufacture of valve seats. The material maintains tight tolerances and creates a reliable seal that keeps systems functioning as intended. The automotive industry also benefits from the material’s capacity to handle corrosive media.

Test Sockets

Precision and reliability are critical in the semiconductor industry, and Vespel® is a great material for test sockets. Its superior dimensional stability and high wear resistance enable consistent, accurate performance during extensive testing cycles. Vespel® test sockets produce optimal results in electronics manufacturing.

Insulators

Another electrical application for Vespel® plastic is the manufacture of insulators that protect various components in electrical and thermal applications. This is possible thanks to its impressive dielectric properties and thermal resistance.

Vespel® plastic parts minimize energy loss and prevent electrical failures in high-voltage systems. Insulators are useful in cutting-edge technologies, such as aerospace systems and advanced electronics.

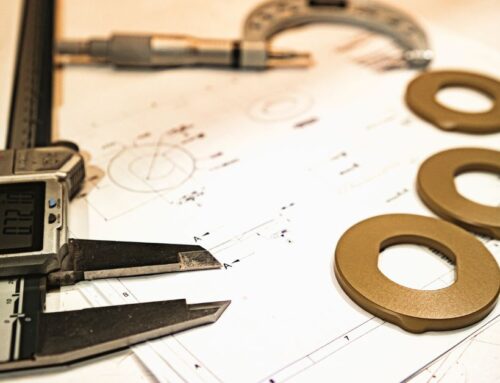

Thrust Washers

Vespel® thrust washers are indispensable for axial or linear movement. These washers provide low friction and high wear resistance, making them ideal for use in mechanisms requiring durability and smooth operation.

Vespel® thrust washers consistently deliver exceptional performance, minimizing frictional losses and ensuring efficient power transmission. With Vespel® thrust washers, engineers can confidently design systems that exhibit optimal performance and longevity.

These examples show how Vespel® plastic can benefit engineers seeking high performance in various applications. Contact Plastic Machining Inc. today to learn about how we can help you create components to fit your project.