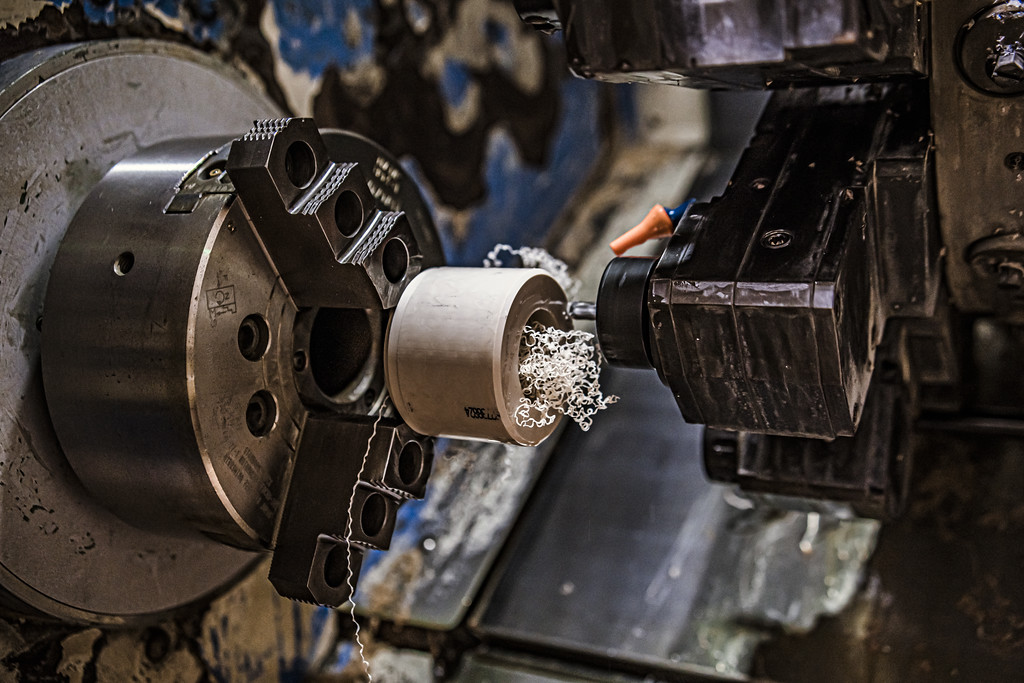

PEEK PLASTIC MACHINED PARTS

PEEK plastic is a revolutionary material that has taken the industry by storm. Its unique properties and versatile nature are to thank for its skyrocketing popularity. Plastic Machining Inc. has mastered the art of PEEK machining, and we now deliver some of the best products out there. This engineering thermoplastic is known for its excellent chemical resistance, high-temperature resistance, and exceptional mechanical properties. It is commonly used in a wide range of industries, including aerospace, medical, and automotive. We’ve made significant strides in ensuring that the PEEK parts we machine meet the industry’s highest standards. So, if you’re in search of quality, long-lasting PEEK plastic parts, look no further than Plastic Machining Inc. With our experience, dedication, and high-quality workmanship, you can be sure you’re getting the very best.

PEEK or polyetheretherketone offers engineers a high-performance, extremely durable thermoplastic that suits challenging applications in multiple industries. As a semicrystalline engineering thermoplastic of the polyaryletherketone (PAEK) family, it maintains high-temperature tolerances, strength, and stability across harsh environments operating continuously at temperatures of 480°F (250°C) without permanent loss in physical properties. For hostile environments, PEEK is an alternative to fluoropolymers.

PEEK plastic materials maintain their strength and durability against chemicals, fatigue, and creep. Its density and tensile strength are high enough to rival metals like aluminum, and it will not degrade in chemically or physically harsh environments as metals do. PEEK also has distinctive properties that make it ideal in biocompatibility, UV resistance, pure radiolucency, gamma-ray resistance, and low/no toxicity in all forms.

Additionally, PEEK’s low coefficient of friction and ability to withstand high loads make it an excellent choice for applications requiring precise and reliable performance. This includes use in semiconductor manufacturing, where contamination-free environments are critical. Furthermore, the inherent flame retardancy and low smoke emissions of PEEK plastic enhance its suitability for electrical and electronic applications, ensuring safety and reliability.

Our latest grade, PEEK LSG (Medical Grade) & PEEK HPV, offers outstanding properties that can be viewed below.

Benefits of Peek

- High-temperature resistance

- High tensile and flexural strength

- Good wear and abrasion resistance

- Outstanding chemical resistance

- Excellent electrical properties

- Excellent fatigue, stress-crack, and creep resistance

Enhanced compressive strength and stiffness

Inherently good wear and abrasion resistance

Increased fluxural modulus of Peek

Performs at temperatures of above 300° F (150°C)

Excellent Chemical Resistance

Highest Elongation and toughness of all Peek grades

Steam and wear resistance

Unfilled 1000 Peek performs to 320°F (160°C)

Injection molded shapes for thin wall rings, extruded

rods and sheets for machined parts, compression molded tubes,

rods and sheets for heavier cross-section parts

United States Pharmacopoeias (USP) and ISO 10993-1 approved

Pre-qualified bio-compatible materials

Lowest coefficient of friction

best Machinability of Peek grades