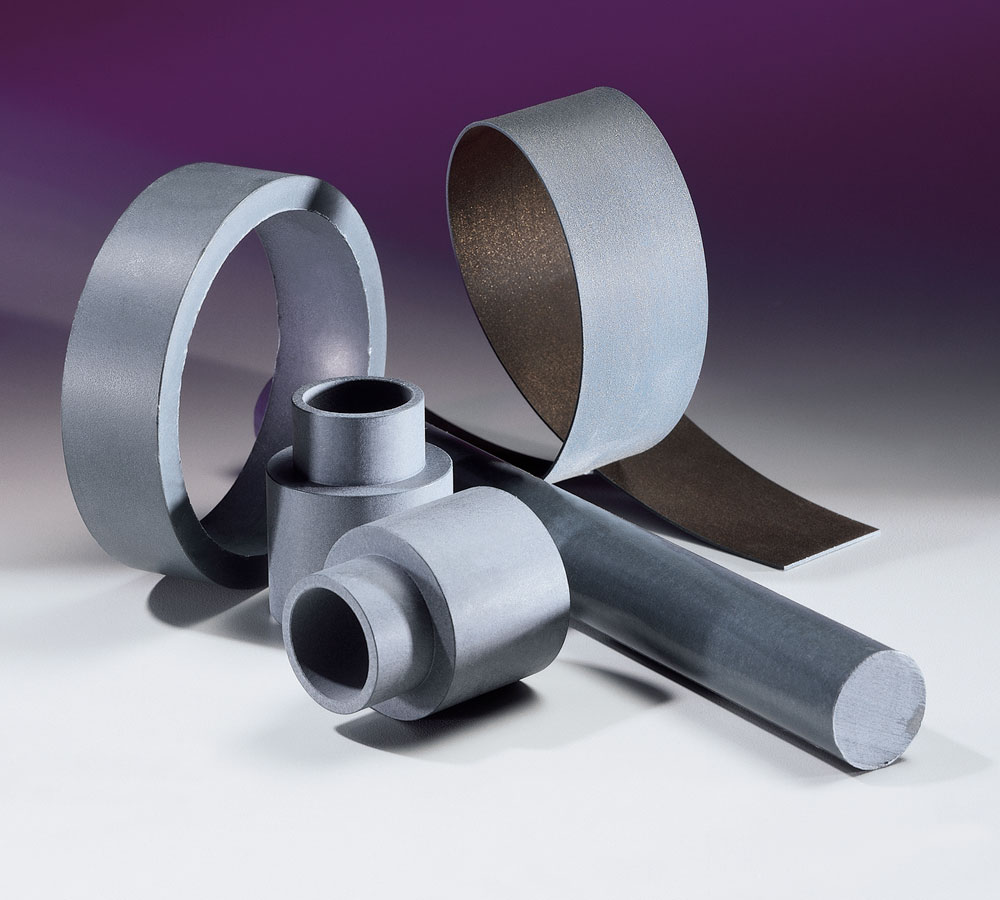

Back to Rulon®

Rulon® 142 material is used for extremely heavy loads, and it is ideal for linear bearing applications such as slide ways in machine tools and heavy equipment. It may also be used in expansion joints and bridge pads. Rulon® 142 material provides low friction, excellent non-lubricated wear properties, and good heat dissipation. It is etched on one side for adhesive bonding to the steel substrate and competes with Busak+Shamban’s Turcite® B product. Color: turquoise with a bronze tint.

Notable Material Features

- High compression strength

- Low coefficient of friction

- Excellent abrasion and corrosion resistance while running without lubrication

Grades of Rulon®

| Rulon LR Properties | |

|---|---|

| Temperature – Typical Range ˚F (˚C ) | -400/+550 (-240/288)* |

| Maximum PV (continuous)(MPa+m/s) | 25,000 (0.88)* |

| Maximum P – psi (static)(MPa) | 10,000 (0.35)* |

| Maximum V -SFM (no load)(m/s) | 400 (2)* |

| ShaftHardness – Minimum | Rb35 |

| Shaft finish recommended Ra (min/um) | 8 – 16 (0.2-0.4)* |

| ShaftMaterial | Mild/HardenedSteel |

| Products | Applications |

|---|---|

| Automatically molded bearings & components | Printers |

| Sleeve,flanged and thrustbearings | Copiers |

| Piston Rings | Air Compressors |

| Stamped and formed seals | Appliances |

| Extruded shapes | Automotive |

| Machined parts | Insulators |

| Molded shapes | Linear slides |

| Anemometers |

| Engineering | |

|---|---|

| Friction – static & dynamic | .0.25 with oil |

| Flammability ASTM D635 | Non-Flammable |

| Chemical Resistance | No acids or bases |

| Thermal Conductivity | 4.8 |

| BTU/hr/sq.ft./˚F/in. | 4.8 |

| Linear Coefficientof (78˚-200˚F) | Diameter 4.9×10-5 (8.8)* |

| Thermal Expansion (26˚ -93˚C) | Length 4.9×10-5(8.8)* |

| Physical Data | |

|---|---|

| Elongation ASTM D638 | 200% |

| Tensile Strength ASTm D638 (MPa) | 3100 PSI (13.8) |

| Deformation (1500 psi – 24 hr. RT) | 3% |

| Specific Gravity | 3.16 |

Rulon® is a registered trademark of Saint-Gobain Performance Plastics Corporation.