When companies need plastic components for various applications, they can either manufacture these parts on their own or turn to a custom manufacturer. The latter can be a practical solution for numerous industries requiring the efficient delivery of precise parts. Learn about the advantages of custom-machined plastic parts in this blog.

CNC Manufacturers Use High-Quality Equipment

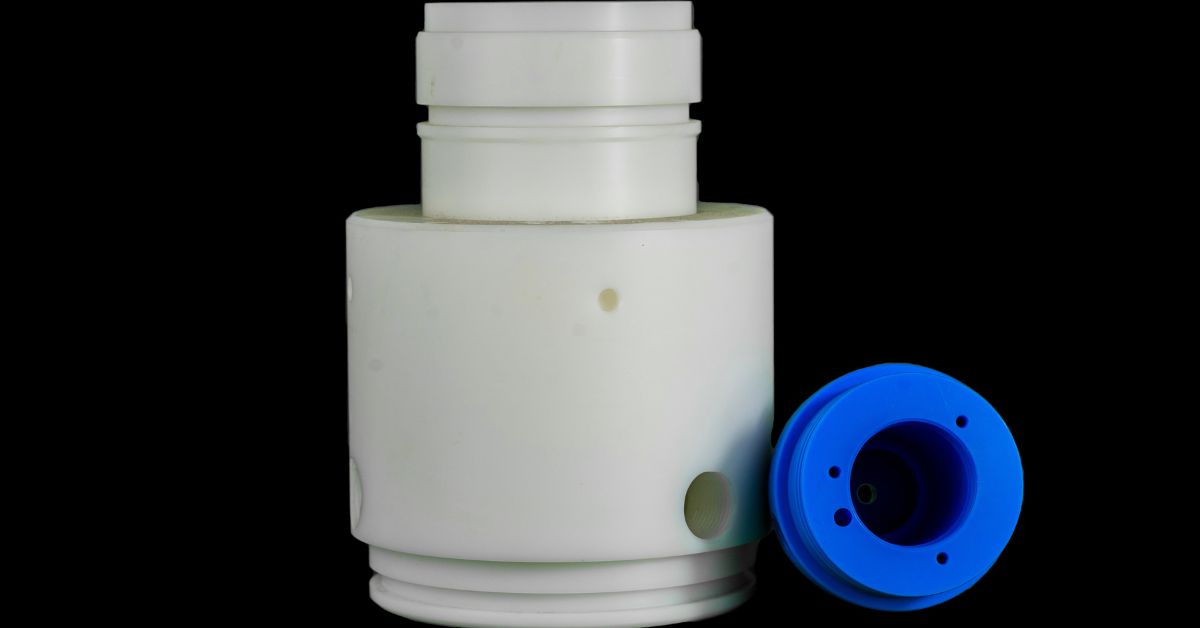

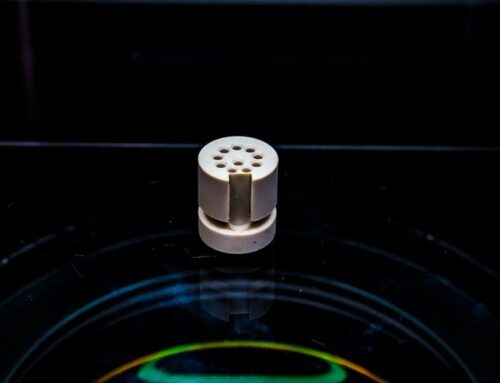

One reason to source custom-machined plastic parts is that manufacturers often use advanced CNC machines in their work. These machines operate with remarkable technological sophistication, allowing suppliers to fabricate items that meet precise engineering specifications.

The use of high-quality equipment also reduces errors related to material deformation or imprecise cutting. For example, if an aerospace client needed Torlon® parts for a new aircraft, a CNC manufacturer would be able to provide those components with impressive precision. Their machines will allow you to obtain parts that meet the stringent standards of your applications.

They Can Meet Tight Production Schedules

Another reason to purchase custom-machined plastic parts is that CNC manufacturers understand the time constraints that engineers deal with during projects. By combining technical expertise with optimized production systems, they consistently meet deadlines without compromising product quality.

CNC machines offer rapid and efficient production capabilities, enabling them to meet high-volume orders when needed. For example, if a food company needed Acetal gears by a certain date, the manufacturer would be able to meet that deadline.

This allows customers to stay competitive while decreasing the workload in their own operations. Engineers working on time-sensitive projects also benefit from such reliable delivery.

Custom Manufacturers Can Serve Multiple Sectors

Flexibility is an essential component of CNC plastic machining. Custom manufacturers can deliver tailored solutions for a wide spectrum of industries and accommodate diverse demands across different sectors.

For instance, if engineers in the medical field require PEEK components for patient procedures or if clients in the semiconductor industry need Ultem® components that can endure hot temperatures, custom manufacturers have the tools and expertise to address these needs. This empowers engineers to meet sector-specific challenges with confidence.

Utilize a CNC Manufacturer Today

These advantages show how custom-machined plastic parts offer unmatched benefits for engineers seeking precision and efficiency in their projects. By choosing solutions rooted in innovation and reliability, you can position your firm for better outcomes.

One company that offers the winning combination of high-quality equipment and extensive manufacturing expertise is Plastic Machining Inc. Contact us today so that we can start helping you obtain the components you need with the efficiency you deserve.