When manufacturers need an alternative to metal, they often turn to polyetheretherketone, also known as “PEEK.” This durable polymer features many properties that make it an increasingly popular material for critical applications.

If you are unfamiliar with the benefits of using PEEK, it is time to learn about them. Discover the advantages of PEEK polymers over metal in this blog from Plastic Machining Inc.

PEEK Weighs Less Than Metal

One significant advantage PEEK plastic has over many common metals is its lighter weight. This allows it to play roles in industries like aerospace and automotive, where every ounce matters.

Lighter components help improve fuel efficiency and reduce energy demands without compromising structural integrity. Reduced weight also allows for easier handling during manufacturing and assembly, saving time and effort during production.

It Can Resist More Chemicals

Another advantage of PEEK polymers over metal is that they offer manufacturers more chemical resistance. PEEK withstands aggressive chemicals, including several acids and solvents, which often corrode or degrade metals over time.

Components that experience exposure to harsh chemical environments benefit from the resilience of this polymer. It helps extend their operational life and reduces the frequency of replacements. Its chemical resistance makes it invaluable for use in oil and gas processing and chemical plants.

PEEK Polymers Can Endure Higher Temperatures

High-temperature environments can pose challenges for metal materials. However, PEEK polymers can tolerate sustained temperatures up to 500 degrees Fahrenheit without deforming or losing mechanical strength. This superior thermal endurance provides a strategic advantage in sectors requiring high-performance materials, such as electronics or aeronautics.

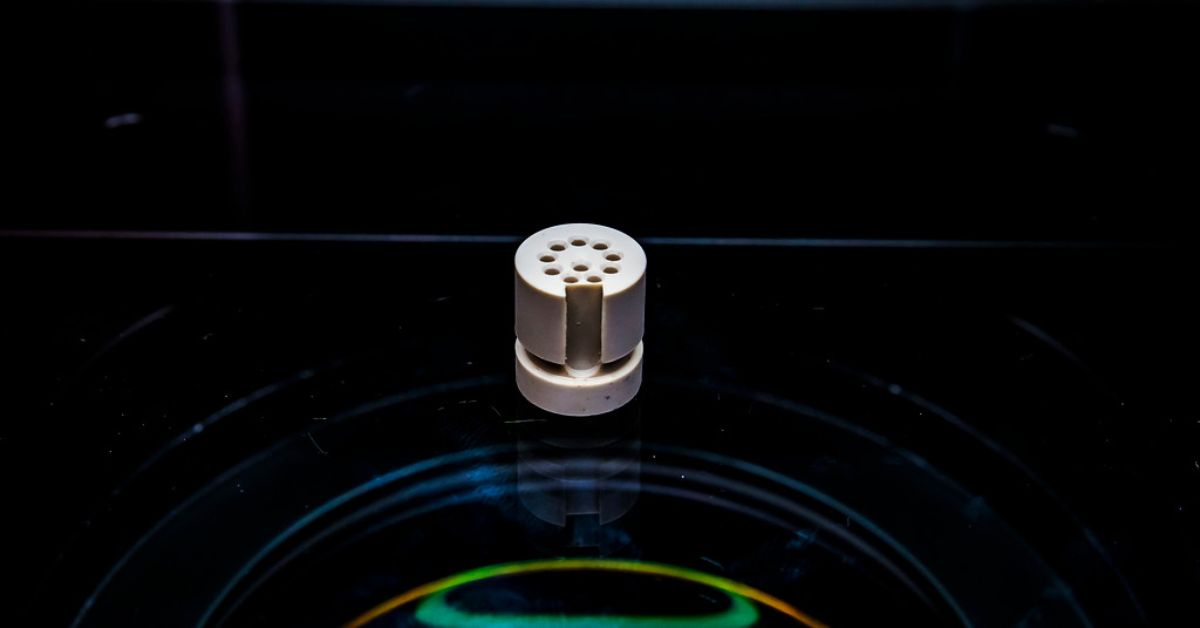

Manufacturers Have More Flexibility With PEEK

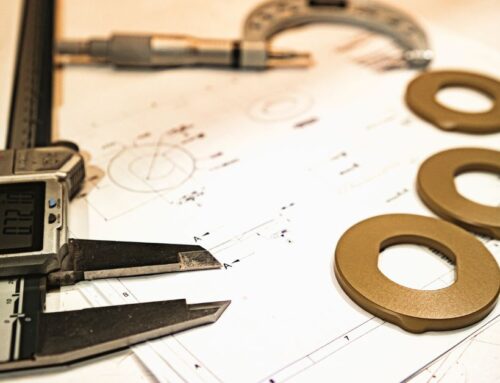

PEEK polymers also offer more design flexibility to manufacturers and engineers. Unlike metals, PEEK can undergo precision molding into complex shapes while maintaining tight tolerances.

This opens opportunities to create components with intricate geometries, reducing the need for secondary machining processes. Manufacturers gain the ability to streamline production workflows and achieve consistent quality without sacrificing performance. Its versatile fabrication potential makes it a responsive choice for prototypes, high-volume runs, or custom solutions.

PEEK Works as an Electrical Insulator

Manufacturers also find PEEK to be an effective electrical insulator. Its insulating properties prevent electrical currents from flowing through components, which is critical for electronics, medical devices, and other applications with strict safety requirements.

Metals, which are inherently conductive, often require additional coatings or layers to meet insulative needs. The inherent dielectric properties of PEEK can simplify manufacturing processes while ensuring reliable performance.

Experience PEEK’s Advantages Today

These examples show how PEEK polymers have redefined what high-performance materials can achieve, proving themselves as strong contenders against traditional metals. From reducing weight to withstanding heat and chemicals, PEEK offers clear advantages that align with the needs of modern industries.

Plastic Machining Inc. can help you experience these benefits firsthand with our PEEK machined parts. We can provide you with components that will stay strong as you utilize them in demanding applications.