When you need plastic components for your application, it is essential to find a manufacturer who can reliably deliver exceptional, precise products while adhering to industry standards. That’s why engineers should partner with an ISO-certified manufacturer. Review this blog from Plastics Machining Inc. to learn the advantages of working with an ISO-certified manufacturer and how they can bring significant value to your projects.

Certified Manufacturers Follow Industry Rules

One reason to seek out ISO-certified manufacturers is that they operate under strict international standards that promote consistency and reliability. These standards ensure that every aspect of the manufacturing process aligns with industry regulations, from material selection to operational procedures. By working with certified manufacturers, engineers can avoid compliance issues and benefit from well-documented processes that uphold the integrity of their designs.

They Will Provide a Quality Product

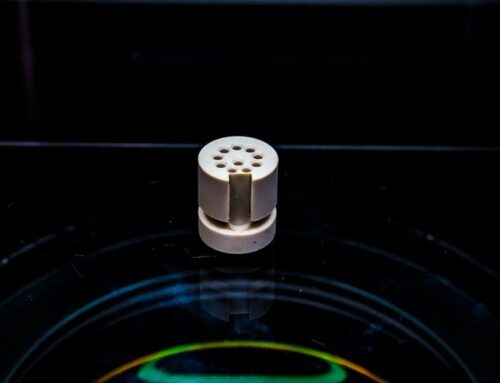

Another advantage of working with an ISO-certified manufacturer is that you can feel more certain that you will receive a high-quality product. Delivering a product of such a high standard requires structured systems and a continual focus on excellence—principles built into every ISO-certified manufacturer’s workflow.

Certification confirms that their products meet stringent performance and durability requirements. Engineers benefit from robust materials and precision engineering, creating confidence that their designs will perform as intended under required conditions.

You Will Have Savings Opportunities

You should also seek out plastic fabrication services from ISO-certified manufacturers because they will give you more opportunities for savings. These companies streamline their processes and eliminate inefficiencies.

This focus reduces waste and errors, offering clients a chance to pay lower costs without sacrificing quality. Additionally, the consistent quality of their products minimizes the likelihood of delays.

ISO Manufacturers Focus on Continuous Improvement

When you utilize an ISO-certified manufacturer, you are employing a company that does not rest on its laurels. Its certification requires the firm to continuously improve so that it will stay ahead of industry advancements and changing demands.

These manufacturers must actively refine their technologies, processes, and techniques. This forward-thinking approach ensures that these manufacturers will adapt to innovations, improving both service and product results over time.

Seek Out an ISO-Certified Manufacturer

These advantages make it clear that engineers should seek out ISO-certified manufacturers. Their dedication to compliance, quality, efficiency, timeliness, and innovation can elevate your project.

One ISO-certified manufacturer that can help you minimize risks and drive your company’s success is Plastics Machining Inc. With our state-of-the-art equipment and focus on providing high-quality plastic components, we will help you nurture client satisfaction and enjoy long-term growth.