In today’s business world, many industries—including aerospace, electronics, and military and defense—rely on custom manufacturers. These companies specialize in delivering tailored solutions to meet diverse industrial and customer needs. However, this sector did not reach its current state overnight.

This sector relied on the development of various technologies and materials that have helped it evolve over the years. Read on to learn about the origins and evolution of custom plastic fabrication.

The Development of Parkesine

The story of plastic fabrication began with the creation of Parkesine, which Alexander Parkes introduced in 1862. He derived this plastic from cellulose, and it became an effective substitute for ivory.

Users could heat, mold, and cool Parkesine into a durable form. Although it posed some early challenges with durability, it definitively demonstrated the potential for manufactured plastics. This innovation catalyzed an era of experimentation and laid the foundation for what the manufacturing world would later achieve.

The Creation of Injection Molding

Another important milestone in the origins and evolution of custom plastic fabrication was the development of injection molding. This arrived as a breakthrough invention in the late 19th century, offering a more efficient way of mass manufacturing plastic products.

Pioneers John Wesley Hyatt and his brother Isaiah Hyatt developed this method using celluloid, an early thermoplastic. Instead of manually shaping plastic, the Hyatts created a mechanism to heat the material and inject it into molds under pressure. Injection molding grew in sophistication over time, becoming a linchpin in custom plastic machining.

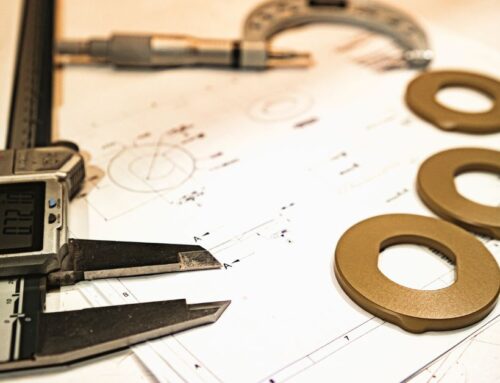

The First Application of CNC Manufacturing

When computer numerical control (CNC) manufacturing entered the scene in the mid-20th century, it reshaped the trajectory of precision plastic fabrication. By automating machining processes with computers, CNC technology made it possible to fabricate highly accurate plastic components. The integration of CNC controls marked a major leap, as manufacturers could achieve unparalleled customization and replicate highly complex designs across multiple pieces.

CAD and CAM Revolutionize CNC Manufacturing

The introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) software in 1972 forever changed CNC manufacturing. These tools advanced the capabilities of CNC systems by enhancing design precision and manufacturing efficiency.

This technology gave manufacturers the ability to produce designs with minimal error margins. CAD and CAM technology also streamlined communication between engineers and production teams, elevating efficiency and simplifying otherwise tedious processes.

The Launch of 3D Printing

The introduction of 3D printing in the 1980s added even more possibilities to custom plastic fabrication. Rather than subtracting material as traditional machining methods do, 3D printing builds objects layer by layer.

This additive technique gives manufacturers the flexibility to experiment with concepts and produce prototypes more affordably. Over time, advancements in 3D printing expanded its capabilities, allowing it to fabricate lightweight yet durable components for industries like medical and consumer electronics. Today, companies use plastics like PEEK and nylon to manufacture components via 3D printing.

Evolve Your Processes With Plastic Machining Inc.

The history of custom plastic fabrication reflects continuous innovation at every stage, from the invention of Parkesine to 3D printing’s game-changing possibilities. Each milestone highlights how creativity and technological strides have reshaped manufacturing.

One company that will continue to stay in step with industry strides is Plastic Machining Inc. We focus on using innovative equipment to deliver plastic components that will meet your exact specifications.