Torlon® 4203 PAI

Electrical or High Strength Applications

Torlon® 4203 PAI (Polyamide-imide) offers excellent compressive strength and the highest elongation of the Torlon® grades. It also provides electrical insulation and exceptional impact strength. This grade is commonly used for electrical connectors and insulators due to its high dielectric strength. Torlon® 4203 has the capicity to operate at 500°F continuous service temperature which makes it ideal for structural components such as linkage and seal rings. Torlon® 4203 PAI is harder at 400°F than other engineered plastics is also an excellent choice for wear applications involving impact loading and abrasive wear.

ISO 9001:2008 Certified

Torlon 4203 PAI is unreinforced, Lubricated, pigmented grade of polyamide-imide (PAI) resin. It has the best impact resistance and greatest elongation of all the Torlon grades. Torlon PAI has the highest strength and stiffness of any thermoplastic up to 275 °C(525°F). It has oustanding resistance to wear, creep, and chemicals.

connectors, switches and relays. In addition Torlon 4203 polyamide-imide can be used in applications such as thrust washers, spline liner, valve seats, bushings, wear rings, cams and applications requiring strength at high temperature and resistance to wear.

- High Flow: Torlon 4203 – HF

- Low Flow: Torlon 4203 – LF

Application Overview

-

Proven Applications

High Temperature Electrical Connectors

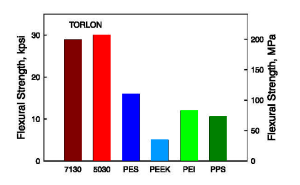

High Temperature Electrical ConnectorsTorlon 4203 PAI and Torlon 5030 PAI provide outstanding electrical performance and high temperature stability. (Prior materials: Nylon, Quadrant PPS, Duratron® PEI)

Bearing Cages

Bearing CagesTorlon 4203 and 4301 PAI’s low expansion rate and excellent wear resistance enable manufacturers to increase bearing speeds and extend part life. (Prior materials: Steel Cages, Hardened Steel Balls, Bronze Bushings)

Can Mandrel

Can MandrelTorlon 4203 PAI’s extraordinary compressive strength and abrasion resistance permit higher production rates, longer part life, and increased support of aluminum cans during printing. (Prior materials: Nylon, UHMW, Ceramic-coated Steel)