Plastic machining is essential in industrial manufacturing and engineering. It offers precise and versatile parts that are crucial for many daily operations. Whether you’re an experienced manufacturer or just getting your business started, understanding what to look for in a plastic machining company can make a significant difference in the quality of your projects and your efficiency in producing them. Browse this guide from Plastics Machining Inc. to learn more about how to select the best machining company as your supplier.

Who Needs a Plastics Machining Company?

Industrial manufacturers and engineers often require specialized parts. These parts must meet specific design and functional requirements, which is where a plastic machining company becomes invaluable. These companies can produce high-quality, precision-machined plastic components for various industries, including automotive, aerospace, medical, and consumer goods.

Smaller businesses also benefit from working with plastic machining companies. They may not have the resources to invest in expensive equipment and trained staff. Working with a specialized provider ensures they still get the necessary quality components.

Educational institutions and research facilities might also require the services of a plastic machining company. Custom-designed plastic parts can support experimental apparatus and prototypes that help advance research and development.

Why Choosing the Right Company Is Important

Selecting the wrong plastic machining company can lead to production delays and subpar components, leading to poor quality manufacturing and damaging your company’s reputation. A reliable partner will help you avoid these pitfalls and help your project run smoothly.

The right company will also offer valuable insights and suggestions. This expertise can improve your designs and manufacturing processes. They can identify potential problems before they arise, saving your business time and money.

What To Look for in a Plastics Machining Company

When evaluating plastic machining companies, you should consider several factors. These factors will help you identify the best partner for your needs. Keep reading to learn what you should look for before partnering with a plastics machining company.

Experience and Expertise

While not a hard and fast rule, a company’s expertise often speaks to its capabilities. Look for a provider with a track record in your industry. This experience ensures they understand the unique challenges, trends, and requirements in your industry. Consider how long they have been in business and the past projects they have handled.

Expertise is equally important. The company should employ skilled technicians and engineers who are well-versed in plastic machining techniques. Their knowledge and work impact the final product’s quality. Don’t forget to ask about their team’s credentials. Certifications and ongoing training indicate a commitment to staying current with industry advancements.

Well-Maintained Equipment

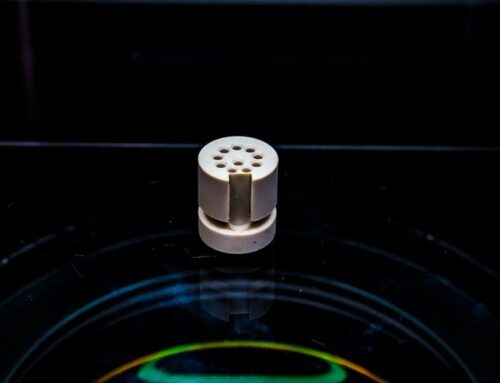

The equipment a machining company uses also influences its products. Modern, well-maintained machinery ensures precision and efficiency. Ask about the types of machines they use and their maintenance schedules. The type of equipment they carry allows them to perform different services and create different products, such as using 3D plastic machining to manufacture custom solutions.

Advanced equipment can handle complex designs and tight tolerances. Ensure the company has the necessary tools to meet your project’s specifications.

Inquire about their capabilities for producing prototypes and small batches. Some companies specialize in large-scale production, while others excel in smaller, custom projects.

High-Quality Materials

Different projects require different materials. A good plastic machining company should offer a variety of options. Common plastic machining materials include CPVC, PVC, PPS, and more. Each material has unique properties that make it suitable for specific applications.

Ensure the company sources high-quality materials from reputable suppliers to guarantee the durability and performance of your components. Ask about their material certifications and quality control processes.

Quality Assurance Standards

Quality assurance is critical in plastic machining. The company should have stringent quality control processes in place. These processes ensure that each component meets the required specifications.

Ask about their inspection and testing procedures. Do they use advanced metrology tools to verify dimensions and tolerances? What steps do they take to ensure consistency across multiple batches?

Efficient Turnaround

Time is money in manufacturing and design projects. You’ll want to find a plastics machining company with efficient production processes to minimize lead times without compromising quality.

Ask about their typical turnaround times for various project sizes. Can they accommodate urgent requests? Flexibility in scheduling can be a significant advantage for meeting tight deadlines.

Do They Offer Custom Solutions?

Every project is unique, and a one-size-fits-all approach doesn’t always work. A superior plastic machining company should offer custom plastic machining solutions tailored to your specific needs. These solutions may involve custom tooling, unique material requirements, or specialized finishing processes.

Custom solutions often require collaboration and innovation. Look for a company that values open communication and creative problem-solving. This will allow you to discuss your projects in detail and describe exactly the types of custom parts you’re looking for.

Reviews and Testimonials

Customer feedback is a valuable resource when evaluating plastic machining companies. Reviews and testimonials provide insights into the company’s performance and customer satisfaction. Look for consistent yet realistic positive feedback and examples of successful projects.

Reach out to past clients if possible—ask about their experiences and any challenges they faced. This firsthand information can help you make an informed decision.

Additionally, consider the company’s industry reputation. Are they known for their reliability, quality, and customer service? A strong reputation is a good indicator of a trustworthy partner.

Communication and Customer Service

Effective communication is crucial for a successful partnership. Look for a plastic machining company that is responsive and transparent. Clear communication helps you outline your project goals and develop an understanding of the parts you need.

Customer service is equally important and a major part of communication. Look for a company that prioritizes your needs and is committed to your satisfaction. A supportive, customer-focused approach can make a huge difference to your project’s success.

Where To Find a Reputable Plastics Machining Company

Finding a reputable plastic machining company can seem daunting, but several resources are available to aid your search. Networking with industry peers and seeking recommendations from trusted colleagues can lead you to reliable partners.

If you’re looking for a great resource that prioritizes the aspects above and more, consider reaching out to Plastic Machining Inc. Our experienced team is known for our commitment to quality and our wide range of product and service offerings.

Selecting the right plastic machining company is a crucial step in building any industrial manufacturing business. By considering the factors above, you can identify a reliable partner. The right company will meet your current needs and support your growth and innovation. Take the time to research and evaluate potential partners. A strategic partnership can drive your business forward and promote successful manufacturing efforts.

If you’re ready to explore top-tier plastic machining solutions, browse our website at Plastic Machining Inc. Our expert team is here to help you achieve your goals with precision and excellence.